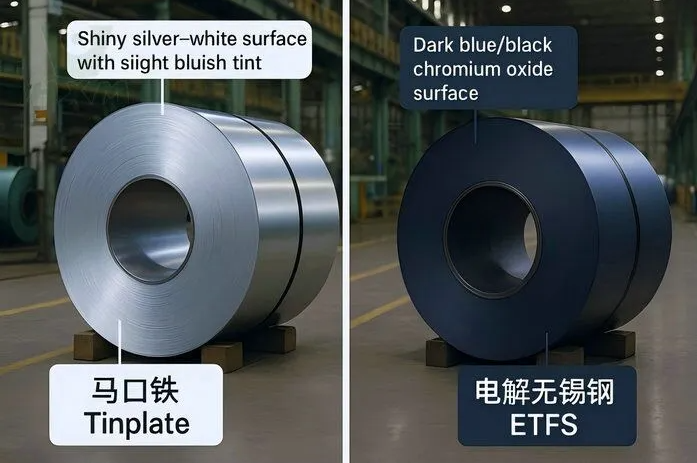

The journey of tinplate, from raw steel to a packaged product ready for global shipment, is a precise and integrated industrial process. It begins with the cold rolling of steel slabs into thin strips. This is followed by a crucial annealing process to soften the steel and enhance its formability. The core step is electrolytic tinning, where a microscopic layer of tin is electroplated onto the steel surface, providing excellent corrosion resistance and a bright, solderable finish. The tinplate is then cut into sheets or coiled, forming the primary material for countless containers.

Following production, the tinplate enters a systematic packing phase for shipment. Sheets or coils are first stacked on robust wooden or steel pallets for stability. They are often wrapped in waterproof paper or plastic film to guard against moisture, a critical measure for sea freight. Protective films or interleaving papers are used to prevent surface scratches on premium grades. The palletized units are then securely strapped with steel or plastic bands to prevent shifting during transit.

The packed pallets are then loaded into standard shipping containers. Coils are often packed upright, while sheets are stacked horizontally, to optimize space and weight distribution. Each container is clearly labeled with details like grade, size, lot number, and destination. This meticulous process ensures that the tinplate arrives at manufacturing plants worldwide in pristine condition, ready to be transformed into cans, containers, and the ubiquitous packaging we rely on every day.