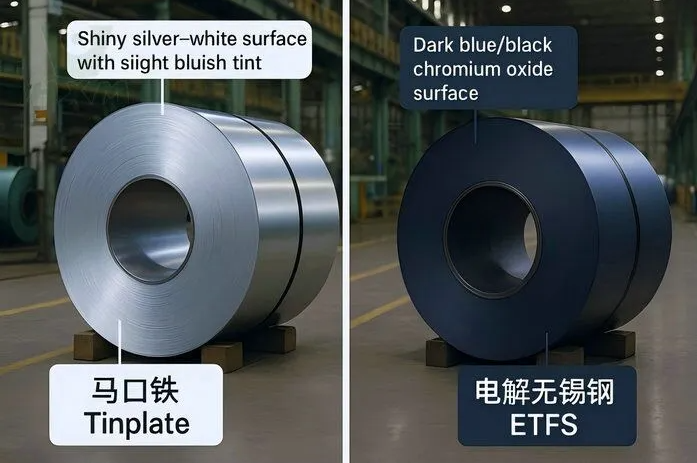

inplate Production and Printing Process The creation of printed tinplate is a sophisticated two-stage journey, transforming raw steel into vibrant and durable packaging. Stage 1: Tinplate Manufacturing The process begins with cold-rolled steel. The steel first undergoes electrolytic cleaning to remove impurities. It then enters the annealing furnace, where it is heated and cooled to soften it and grant the required ductility. The core step is electrolytic tinning: the steel strip is passed through an acid bath and then into an electrolytic cell, where a precise, microscopic layer of tin is deposited onto both surfaces, providing corrosion resistance and solderability. Finally, the tinplate is chemically treated (passivation) to prevent oxidation and enhance paint adhesion, before being cut into sheets or coiled. Stage 2: Printing and Coating The printing of tinplate primarily uses high-speed, sheet-fed offset lithography. Before printing, the sheets are often coated with a white or clear base layer to create a brilliant, uniform background. Specialized inks are then applied, which are formulated to adhere to the metal surface and withstand high-temperature curing. The printed sheets pass through ovens to dry and harden the inks. A protective varnish is typically applied as a final layer, providing gloss, scratch resistance, and a barrier against the packaged product. The finished, printed tinplate is now ready to be formed into cans, lids, and other containers.